Analysis of Quarried Stone in 1805 North Road Farm Barn Foundation

Report by:

James Gage & Mary Gage

www.stonestructures.org

June 2, 2012

Location:

North Road Farm [Private Property]

370 North Road

Fremont NH

www.northroadfarm.com

Historical Information

Matthew Thomas.

History of Fremont, N.H. - Olde Poplin: An Indepedent New England Republic, 1764-1997

Fremont, NH: M. E. Thomas, 1998.

“The Moses Norris – David Robinson – Stephen Sleeper House. This house stood on the site of the present house built in 1977. It was built circa 1805 by Moses Norris (1783-1819). His son Ezekiel Godfrey Norris inherited the house and sold it to David Robinson in 1831. Robinson’s widow sold it circa 1858 to Stephen G. Sleeper and it remained in the Sleeper family until 1957. The 30 x 40 foot 2 ½ story house with 2 story ell, 2 arched carriage stalls and 40 x 60 foot long barn also contained a blacksmith shop, barn yard sheds, carpenter’s shop and lumber loft. This magnificent set of connected New England farm buildings was destroyed by an arsonist in October 1955. The barn was saved. Moses Norris had a tanyard and bark house on the property during his time of ownership.”

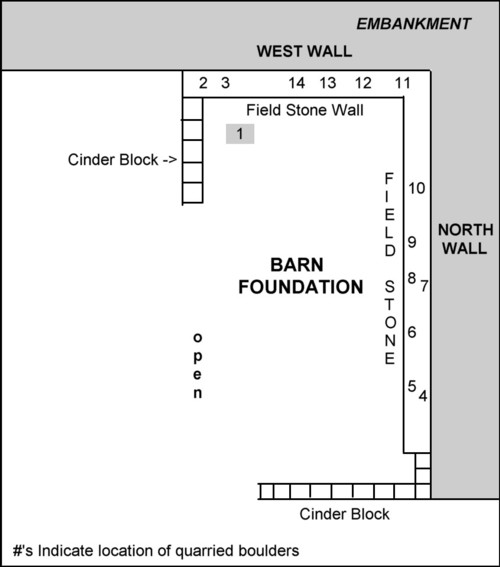

Barn Foundation

The west and north walls of the barn foundation were built of unmortared field stones. Both natural as well as quarried field stones were used. The east wall is modern cinder block. The south wall is open most of the length except for a section of modern cinder block.

A total of fourteen boulders with quarrying marks were identified in the foundation. Nine stones were quarried by the use of a single blast hole drilled in the center of boulder. Five stones were split apart using the flat wedge method.

Blasted Boulders

Technique

A single round hole would be drilled in the top center of a field boulder using a plug drill or star drill. The drill was hit with a hammer and rotated a 1/8 to 1/4 turn and hit again. This process was repeated until the desired depth was reached. The stone dust from the drill was periodically removed with a specialized “spoon.” The hole was partially filled with black powder and the remainder of the hole filled with sand, clay, or stone dust. A fuse was inserted and lit and the boulder was blasted usually into two or three pieces.

Analyze of Examples found in Barn Foundation

Two distinct groups of blasted boulders were identified based upon hole diameter size:

Group #1 - The west wall contained 4 blasted boulders plus one boulder on the floor near the wall (total of 5). All had round holes with a diameter of 7/8” and the length of the holes ranged from 6 ½” to 8 ½” deep.

Group #2 - The north wall had 4 blasted boulders with a hole diameter ranging from 1 1/16” to 1 ¼”. The length of the holes ranged from 11” to 11 ½” (the full length of two of the holes could not be calculated because a portion of the hole was missing).

The two different size diameter holes indicate that there were two distinctly different blasting episodes. The 7/8” diameter holes are found only in the west wall, and the larger 1 1/16” holes are found only in the north wall. This suggests that each wall was built by a different laborer or stone mason. It was common to hire experienced men to handle the blasting work. And, it was also common to contract one man for one portion of a job and another man for a different portion. This was likely the case with the construction of the barn foundation. The work may have been done over a several month period.

Between 1800 and 1805 there was significant transition in the size of blasting holes. The transition was from smaller diameter holes with shorter lengths to larger diameter holes with longer lengths. (The reason for this transition is currently unknown.) The two different blasting episodes found in the barn foundation span both sides of this transition period. This is a unique situation and a valuable contribution to our limited knowledge of pre-1810 blasting history in New England.

Boulders Split With the Flat Wedge Method

Technique

The flat wedge method was developed in Quincy, Massachusetts in 1803. The quarry holes used in this method were cut with a cape chisel. The holes are usually trapezoid shaped in cross-section, although occasionally they tend toward a triangular shape. The quarry holes are usually spaced 3 to 4 inches apart from each other along the length of the rock to be split. Two flat L shaped shims are placed in each hole and a flat thin wedge between the shims. The wedges are tapped with a hammer in sequence along the whole length of the rock. This process is repeated until a cracking noise is heard. The two halves of the rock are then pried apart with a crowbar.

Analysis of Examples found in the Barn Foundation

Five boulders were split using the flat wedge method, two in the west wall and three in the north wall. Four of the boulders have three flat wedge marks and one has a single mark. (The single mark may be misleading in terms of the number of flat wedge holes used to split the boulder. One or more of the marks may have ended up on the other half of the split boulder). The maximum of three holes per boulder suggests that only three sets of wedges and shims were available for splitting the stone. The quarry holes were widely spaced apart to accommodate the limited number of sets. The spacing between holes ranged from 5 to 8 inches. Normally, the holes are spaced 3 to 4 inches apart.

The size and shape of the marks and spacing between them varies between the different split boulders. The most noticeable differences are between quarried boulder #6 and #7. Boulder #6 has marks with well formed flat bottoms whereas #7 has marks that come to a point at the bottom. These differences suggest that at least two different men split boulders with this method. Overall, the holes lack the uniformity of size and shape seen in examples done by experienced quarriers. This suggests that the men did not have a lot of experience with the method. This is not surprising given the flat wedge method was not developed until 1803 in Quincy MA. The men may have been working from a written description or demonstration of the method that they saw. These inconsistencies would be expected for early examples of this method especially outside of the quarries in Quincy, Massachusetts where the method was developed.

The evidence suggests at least two different men were involved in splitting stones with this method. The fact that only three sets of wedge & shims were being used suggests these tools were owned by the farm. The farmer and/or farm laborers may have each tried their hand at this new technique.

Conclusion

The quarrying evidence found in the barn foundation is consistent with the circa 1805 construction date assigned to the barn. The blasting evidence is consistent with a transitional period (circa 1800-1805) in which the sizing of blast holes changed. The flat wedge quarry marks lack the uniformity found on examples done by experienced quarrymen and stone masons. This is consistent with an early an implementation of the method especially prior to the 1810’s.

WEST FOUNDATION WALL QUARRIED BOULDERS

#1 – Blast Hole

7/8” diameter

6½” long

#2 – Flat Wedge Holes

½” to ¾” length at bottom

1½” length at top*

½” width

1” height*

8” spacing

*NOTE: These are only the bottom half of the flat wedge holes. The top 1 inch of the rock has sheared off for unknown reasons. The height and length of the holes do not reflect the original size.

#3 – Blast Hole

7/8” diameter

8½” long

#11 – Blast Hole

7/8” diameter

7” long

#12 – Blast Hole

7/8” diameter

7½” long

NO PHOTO

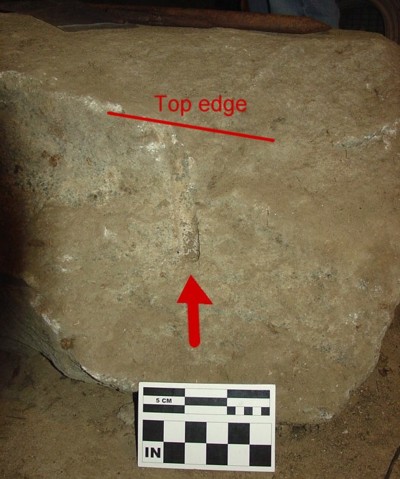

#13 – Flat Wedge Hole (Single hole*)

½” length at bottom

2” length at top

3/8” width

2” height

? spacing

*NOTE: Given that the other examples of flat wedge split stones have several holes, it is likely this stone was split with multiple holes as well. The other holes are probably on the other half of the stone.

#14 – Blast Hole

7/8” diameter

6½” long

NORTH FOUNDATION WALL QUARRIED BOULDERS

#4 – Blast Hole

1¼” diameter

11½” long

#5 – Blast Hole (Partial*)

1 1/16” diameter

1½” long

*NOTE: This is the bottom section of a larger drilled blast hole.

#6 – Flat Wedge Holes

3/4” length at bottom

2” length at top

3/8” width

2” height

5-6” spacing

#7 – Flat Wedge Holes

0 - ¼” length at bottom (pointed)

2½” length at top

3/8” width

2¼” height

7 spacing

#8 – Blast Hole

1 1/16” diameter

11” long

#9 Blast Hole (Partial bottom section)

1 1/16” diameter

3” long

NO PHOTO

#10 – Flat Wedge Holes (faint)

½” length at bottom

1½” length at top

3/8” width

1½” height

6-8” spacing