Carved Grooved Stones

Lye Stones, Cider Press Stones, & Native American Grooved Stones

TABLE OF CONTENTS

Lye Stones

Cider Press Stones

Native American Grooved Stones

History of Lye Stones

Lye / Potash Stone Bases

Lye stones are flat stone bases placed underneath a leaching barrel. They have a circular groove carved into the top surface which was used to collect the liquid lye and funnel it into a collection pot. Lye stones were generally made from hard rocks like granite or gneiss. Lye is a caustic alkaline and a type of stone was needed that would not chemically react with the lye.

All of the known examples of lye stones have a carved circular groove with a second carved groove extended from the circular groove to the edge of the stone. This second groove served as a spout to direct the liquid lye into a collection pot. The grooves are usually shallow in depth. A deep groove was not necessary because of the slow rate at which the liquid lye leached out of the barrel. The grooves were generally carved with whatever tools were readily available. They range from very rough grooves chipped out with various types of hammers to well formed V shaped grooves done with chisels.

Distinguishing Lye Stones from Cider Press Stones

Lye stones are distinguished from apple cider press stones by the size of the groove. Cider presses produced a large volume of liquid and required a wider and deeper groove to handle the volume. Lye stones have a shallower and narrower groove because they handled a lower volume of liquid.

Terminology

Lye – Today the term lye refers specifically to Sodium Hydroxide (NAOH) which was historically known as “caustic soda.” The historic lye derived from leaching hardwood wood ashes and used in soapmaking was primarily Potassium Hydroxide (KOH). It is also known as caustic potash or potash lye.

Potash – Today the term potash refers to several different potassium based compounds: Potassium Hydroxide (KOH), Potassium Carbonate (K2CO3), Potassium Chloride (KCl), etc. Historically, potash was derived from boiling down liquid lye (leached from hardwood ash) until it was reduced to a white solid composed primarily of Potassium Carbonate (K2CO3). Potassium Carbonate was used in soap making, glass production, and other manufacturing processes. It could be further refined in a kiln to remove impurities. The refined product was called pearl ash. Both potash and pearl ash were used as an early leavening agent in baked goods.

*The term lye and potash were sometimes used interchangeable in the historic literature as a name for the liquid lye leeched from the wood ash.

Domestic & Commercial Production

Lye and potash were manufactured on a small scale for domestic household use, as a local cottage industry, and as well as on a commercial scale. The majority of farms in America produced their own lye which was used to make their own soap. There was also a very active cottage industry during the 1700 and 1800’s for the production of potash. Small scale local commercial operations would purchase potash by the pound from city households as well as from farmers. These businesses generally paid cash. Potash became another “cash crop.” These businesses refined the potash at their potash works and sold the refined potash to various European markets. One Philadelphia potash merchant published detailed instructions on how to make potash in the household. He would only purchase potash produced using his precise instructions.

|

Advertisement for the purchase of potash (“salts of lye”) from Hampshire Gazette 5-8-1793

Processing & Equipment

Wood ashes were carefully collected and saved throughout the year. The primary source of wood ash used for lye and potash came from household fireplaces especially during the colonial period. (Lewis 1767: 5) When the Ohio Valley and other portions of the American frontier were opened up, a second source of wood ash was developed. The trees removed during land clearing were burned in large heaps. The ashes derived from the land clearing were processed into potash and the potash sold for cash. (Ostler 2006)

Lye and potash were generally made from hardwood ashes. Hardwood trees contained a higher concentration of lye and potash then did soft woods and was therefore the wood ash of choice. There was a strong preference for oak although a portion of the ash could come from beech, hickory, birch, elm, walnut, chestnut, & maple. (Lewis 1767: 5)

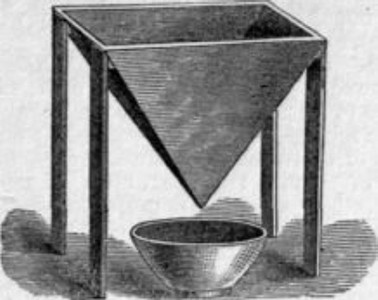

There were three basic types of leeching containers used. The first type was a standard barrel with holes drilled in the bottom of it. (It is also possible that bottomless barrel were used but the period literature generally recommended drilling holes in the bottom.) The barrel was set upon a collection tray (or lye stone) with a spout which was raised off the ground to sufficient height to allow a collection pot to be placed beneath the spout. The second type was a wedge shaped wooden hopper with an opening on the bottom at one end. It drained either directly into the collection pot or into the pot via V-shaped spout underneath it. (Johnson 1913) The third type was a square shaped conical hopper. The four sides of the hopper narrow at the bottom to a small opening. A collection pot was placed underneath the opening. (Dick 1872)

Lye stone with a barrel setup for leaching wood ashes (Old Sturbridge Village).

Photo on right - Courtesy of Prof. Ken Feder, Central Connecticut State University

1913 Photograph of a wedge shaped hopper for leaching lye used in Mississippi (Johnson 1913)

Square shaped conical hopper. (Dick 1872: Entry 550)

In the bottom of the leeching barrel or hopper a filter covered the holes to prevent them from clogging. Generally straw was used as the filter material but other materials like a rug could be used. The ashes were placed in the container on top of the filter material. Sometimes lime was added to the ash mixture especially in the 19th century. The container was filled with water to within a few inches of the top. It was necessary to leave sufficient room at the top to pour the water into the ash mixture. Water was poured into the mixture and allowed to leech out the lye which dripped into the collection pot. Cold water could be used but hot water was generally considered more effective at extracting the lye. The water was occasionally replenished.

There were two schools of thought as to how to handle the leaching stage of the process. One school of thought favored plugging the drain hole and allowing the water and ashes to soak anywhere from 24 hours to a week. After the elapsed time the hole was unplugged and the liquid collected. The second school of thought allowed the water to percolate through the mixture and begin to drip through the hole into the collection container immediately. In a few commercial operations the liquid was poured back into the barrel or hopper on the theory it improved the concentration of lye in the resulting liquid that dripped out. However, this never became a common practice.

The liquid leach was then boiled to increase the concentration of lye. The lye was of proper strength when an egg or potato floated in it. This was a simple but effective specific gravity test. To create potash from the liquid lye, it was boiled down until a white solid formed in the bottom of the pot.

The collection tray could be made from wood or stone. Wooden trays consisted of a flat board with a raised lip around the perimeter and a spout. The other type of tray was a stone slab with a carved circular groove that had an additional groove leading from the circular groove to the edge of the stone. The circular groove would have a diameter slightly larger than barrel.

Bibliography

Anon

1850 Mrs. Leslie’s Lady’s House-Book; A Manual of Domestic Economy. 11th Edition. Philadelphia: A. Hart. [See pages 15-16]

1880 “Soft Soap.” Southern Cultivator v.38 no.2 (Feb. 1880) p.71.

Dick, William B.

1872 Encyclopedia of Practical Receipts And Processes. New York: New York: Dick and Fitzgerald, Publishers. [See entry 550]

Johnson, Clifton

1913 Highways and Byways of the Mississippi Valley. New York: Macmillan. http://www.kellscraft.com/MississippiValley/MississippiValleyCh01.html

Lewis, W.

1767 Experiments and Observations on American Potash. London: Society for the Encouragement of Arts, Manufactures, and Commerce.

Ostler, Craig James

2006 “Church History Sites in Kirtland, Ohio: A Photo Essay,” in Regional Studies in Latter-day Saint Church History: Ohio and Upper Canada, ed. Guy L. Dorius, Craig K. Manscill, and Craig James Ostler (Provo, UT: Religious Studies Center, Brigham Young University, 2006), pp.53–85. Posted on: http://rsc.byu.edu/archived/regional-studies-latter-day-saint-church-history-ohio-and-upper-canada/5-church-history-sit [Has a section on commercial potash production with photos of recreated potash works.]

Stephens, Thomas

1755 The Method and Plain Process for Making Pot-Ash, Equal, If not Superior to the Best Foreign Pot-Ash. London: Printed for R. Griffiths.

Youman, A. E., MD

1872 Dictionary of Every-Day Wants. New York: Frank M. Reed, Publisher. [See “Soap Making” entry]

EXAMPLES

Lye Stone

Old Sturbridge Village, Law Office

Stone – 56 inches (length) x 36 inches (wide)*

Groove Diameter – Oval shape - 44 inches (length) x 32 inches (wide)*

Groove – Width and depth are variable – 1/4 to 1 inch (width), 1/4 to 5/8 inch (depth)*

* Measurements based on photo

Description

This grooved stone is currently the doorstep into the Law Office. There is some wear on the stone from foot traffic. This raises a pertinent preservation issue for this object. The groove has an oval shape, its width and depth are variable. The narrowest sections (~1/4 inch in width) have a clear metal chisel cut groove. The wider sections show a chipping pattern suggestive of a hammer or mill pick being used (The chipping pattern could also be the result of the chisel being worked across the width of the groove rather along the its length). The spout has a width of 3/4 inch and an approximate depth of 1 inch. It has a V shape cut. The spout stands out in sharp contrast to the oval groove because of its greater depth and width.

Discussion

The design, size, and groove cut with metal chisel are consistent with an interpretation of this stone being carved for use as a lye stone.

|

Lye Stone

Old Sturbridge Village, adjacent to Fennol House

Stone – 38 inches (length) x 26 inches (width)*

Groove Diameter – 18.5 inches (average)*

Groove – ¾ inch (wide)*

* Measurements based on photo

Description

The groove is V shaped with one side of the V having a lower angle (slant) than the other side. It has a long spout traversing across a trapezoidal shaped projection on one side of the stone. Rather than being carved as a continuous circle, the groove appears to have been carved as a series segments similar to a octagon. The segments are partially curved giving the appearance of a roughly circular shape. Some of the segment junctions are more peaked than smoothly curved. The stone in the interior of the oval has some discoloration.

Discussion

The V shaped groove is typical of grooves carved with a metal chisel. The lower angle or slant on one side of the V groove is also typical and has been observed on some gravestones and Newbury, MA milestones (see Stories Carved in Stone By Mary Gage & James Gage). The overall shape of stone with its long trapezoidal shaped projection for the spout is similar to a much larger version in front of the Library in Glocester, RI. The Glocester example is an apple press. The smaller size of the OSV example is more consistent with a Lye stone interpretation. The discoloration in the center may be the result of chemical interaction with the lye.

|

Lye Stone

Lye Stone

Voluntown, CT (Private Property) - Photo courtesy of Steve Dimarzo, Jr.

Stone – 31 inches (length) x 27 inches (width)*

Groove Diameter – 20 inches (average)*

Groove – 1/2” inch (wide)*

* Measurements based on photo

Description

This lye is a bit unusual in that the groove for the spout bisect the entire circle rather than just extending from the circular groove to the edge of the stone. The stone itself appears to be a piece of surface ledge that was pried off the bedrock.

|

Lye Stone

Lye Stone

Groton, CT (Undisclosed location) - Photos courtesy of Dan Nelson

Stone – 49 inches (length) x 45 inches (width) x 7 inches (thick)

Groove Diameter – 32 inches (average)

Groove – 1 1/2” inches (wide) x 1 inch (deep)

Description

This lye stone was found in situ on an old farm site. It is located near a large house foundation and stone line well. The spout is formed by an outward “V” shape projection of the circular groove.

CLICK ON PHOTO TO ENLARGE

Lye Stone

Lye Stone

East Hartland, CT - East Hartland Cemetery - Photos courtesy of Prof. Ken Feder, Central Connecticut State University

Stone – 43 1/3 inches (length) x 26 3/4 inches (width)*

Groove Diameter – 19 3/4 inches (average)*

Groove – between 1 1/4 and 1 1/2 inch (wide)*

* Measurements based on photo

Description

This lye stone has been converted into a bench in the cemetery. The rod in the photo is in 10 cm increments. The interesting feature with this lye stone is how the spout was formed. A round hole was drilled through

the stone slab in the outside edge of the circular. The

rock between the hole and the edge of the stone was

knocked off with a hammer.

|

Centerbrook, CT (Private property)

Photo courtesy of Greg Morris

|

Apple Cider Press

Old Sturbridge Village Collection (viewing by appointment only)

Stone – 6 feet (length) x 6 feet 3 inches (width) x 6 inches (thickness)

Groove – 2 ½ inches wide x 1 ½ inches deep

Weight – 18.75 cubic feet x 150 lbs/ft3 (granite) = 2812 lbs

Description

It is roughly a square shaped flat piece of granite with a deep groove around the perimeter of the stone. The groove has a rectangular shaped cross-section. On one side is a drainage spout connected to the groove. The spout is located off-center. On the upper left corner, the groove lacks a squared off junction. The groove extends beyond the junction (fig. 9) and slopes at angle from the top surface of the stone to the depth of the groove at that point it meets the junction.

It is roughly a square shaped flat piece of granite with a deep groove around the perimeter of the stone. The groove has a rectangular shaped cross-section. On one side is a drainage spout connected to the groove. The spout is located off-center. On the upper left corner, the groove lacks a squared off junction. The groove extends beyond the junction (fig. 9) and slopes at angle from the top surface of the stone to the depth of the groove at that point it meets the junction.

Discussion

The carver of this grooved stone began at the non-squared off junction. Using a chisel the carver began the carving by creating a sloped grooved. Once the desired depth was reach (at the junction), the carver chiseled out the groove. At the next three junctions, the carver only needed to change angle of the chiseling 90 degrees to continue carving. No additional sloped grooves were necessary. The spout extends from the groove to edge of the stone. It slopes downward from the level of groove to edge of the stone to facilitate good drainage.

The overall design of this grooved stone, the wide deep groove, and the stone’s overall size is consistent with both wooden and stone bases used for apple presses. It has strong similarity with the wooden cider press in OSV collection and historic wooden and stone base cider presses in Great Britain which are documented in Cidermaking by Michael Quinon (1997, Shire Publications Ltd.).

|

Description

This large slab of surface ledge granite is carved with a circular deep “V” groove with attached spout. The deep “V” groove is characteristic of a metal chisel.

Discussion

The current plague on the stone indicates it was an apple cider press. The size of stone and the depth of the grooves seems consistent with that interpretation.

|

Apple Cider Press

Hadley, MA - Local Museum

Stone - 6 feet 7 inches (width) x 7 feet 10 inches (Length) x 7 inches (depth)

Groove - 3 1/2 to 5 1/2 inches (width) x 1 1/4 to 1 1/2 inches (depth)

Description

The stone is piece granite split or pried off of surface ledge. It has a roughly rectangular perimeter groove with two attached spouts. At one end the grove angles inward following the contour of the outer edge of the stone. The groove varies in width and depth and the angle of its sides . however, one side of groove is nearly vertical while the other side slopes inward at a more gradual angle. Chipping and divet marks are noticeable in the groove. This indicates that the groove was crudely carved with some type of metal hammer (rather than a chisel).

. however, one side of groove is nearly vertical while the other side slopes inward at a more gradual angle. Chipping and divet marks are noticeable in the groove. This indicates that the groove was crudely carved with some type of metal hammer (rather than a chisel).

Discussion

The evidence indicates that this was a historically carved grooved stone. Its layout and size is similar to the cider press stone at Old Sturbridge Village. The local historical society states it was a apple cider press stone and the evidence supports that interpretation.

|

Massachusetts - Westport? Darmouth?

We received this photograph from Steve Dimarzo Jr. It was taken around 1990 possible in Westport or Dartmouth Massachusetts. If you have any information about its exact location, please contact us.

It has two spouts. The groove appears to have carved in a similar method as the Hadley stone.

NATIVE AMERICAN GROOVED STONES

Native American Ceremonial Grooved Waterfall Drain

Mystery Hill, North Salem, NH

Stone - 8 feet (length) x 6 feet 3 inches (width) x 10 inches (thickness)

Groove -

Description

This large slab of surface granite was quarried from nearby surface ledge. It is raised upon three stone columns and the edge of the Oracle Chamber. The “speaking tube” extends from the outside of the chamber under the stone slab to the interior room. The ledge under the raised stone slab has a moderate slope.

The groove is carved around the perimeter of the stone creating a rectangular shape. A single spout is attached to the groove. Below the spout is a V shape notch the ledge. The groove has a shallow rounded shape. The surface of the groove indicates it was carved using a hammer stone. No metal tools were used.

Discussion

This grooved stone has been the subject of many theories. It has been argued it was a cider press. The location of the stone argues against such an interpretation. The groove slab is placed on a moderately slope ledge in a tightly confined area. By far less than ideal conditions for such an operation especially when several large flat expanses of ground are available less than 50 feet away. All historically documented cider press base stones are placed 6 to 18 inches above ground level. This was for a practical reason - the farmer needed to be able to reach the arms of the screw press used to press the apples. This slab is simply to high off the ground to operate the press itself. Combined with the lack of evidence for metal tools, this theory can be soundly rejected.

Archaeological excavations at the site have revealed multiple episodes of Native American quarrying of the surface ledge. The pecked grooves on this stone link it to Native American activity at the site. Mary Gage has argued in America’s Stonehenge Deciphered that this stone grooved stone was an elaborate ceremonial feature. Sacred water poured into the grooves exited the stone at the groove, formed a waterfall which poured into the V shaped notch in the ledge below. A sacred quartz crystal, mined on the site, was placed in the notch where it came into contact with the water. This co-mingling of water and crystals had profound spiritual and symbolic meaning to the Native Americans.

For more information see the expanded article Native American Worked Stones.

|

For more examples please checkout “Lye Leaching Stones and Similar Circle and Line Petroglyphs” webpage at

http://www.megaliths-caves-and-interesting-stuff.org/skywebleach.html